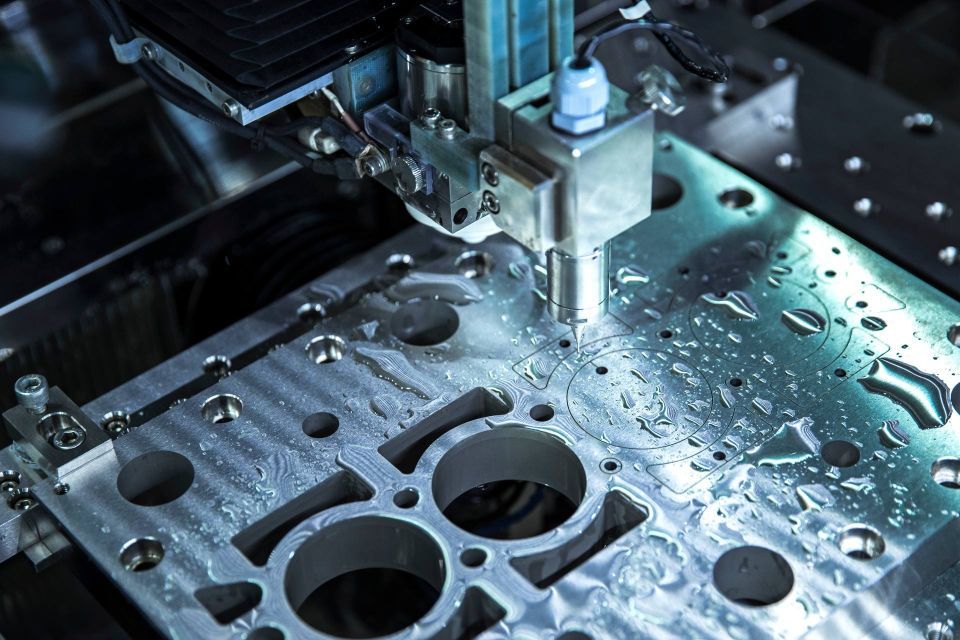

Aluminium and alloy processing with CNC machinery

Since 1991, we have been processing aluminium and alloys with quality and reliability

Aluminum and alloy processing

GBM since 1991 is the ideal partner for high quality and manufacturing precision using numerically-controlled mechanical processing.

Production and customer service

Technological innovation

Numerical control machining for the supply of valves, cylinders and other components to companies.

Staff training

Continuous professional development of operators to guarantee faster technological services.

Direct and fast delivery

Direct and fast delivery

The high tech machine fleet is able to ensure punctuality of all processing required.

Pre- and post-sale assistance

At the customer's side both for the design phase and for testing of the components.

Production and customer services

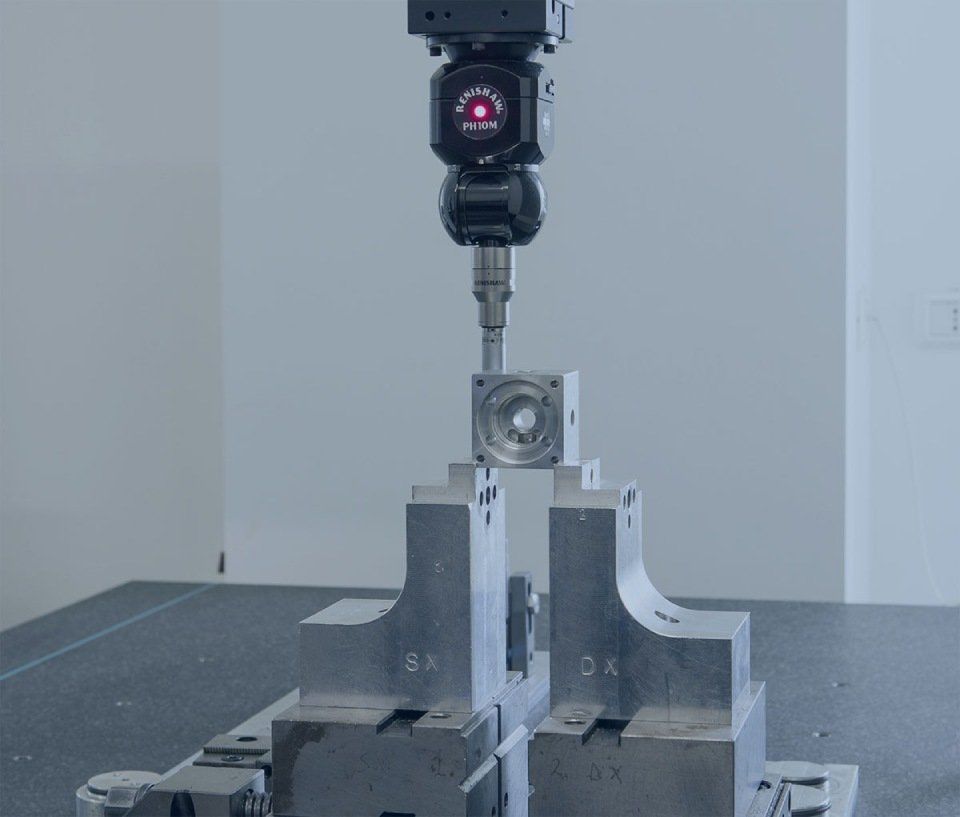

Each and every component is made with numerically-control machinery with 3, 4 and 5 axes, capable of complex precision mechanical processing, overseen by a modern measuring room for scrupulous control over the production cycle. This room verifies the tolerances indicated in the technical drawing. Respect for deadlines and customer service are essential values in the GBM quality management system. Each order is subject to technical advice, feasibility analysis with simulations to establish any critical issues, production costings and production processes, all following Industry 4.0 logic. Finally, each order is sent to production and checked in real time until delivery.